Is your dream to sell T-shirts? Then now is the time to start exploring your printing options!

We think you’re ready to create your own LEGIT clothing line. But there are so many printing options out there. Deciding on the right one can be confusing. How do you know what way is best?

Don’t worry. We’ve got you and all your questions covered!

We’ll give you the low-down on print on demand services, how to print custom apparel, and show you the “do’s and don’ts” of making your own T-shirts. After you read this article, you’ll be able to better navigate your way through the world of apparel production for startups and small businesses and do so successfully. Best of all, we’ll show you exactly which production method(s) is most profitable for entrepreneurs just starting out with an online clothing brand.

Use the tools we provide here, commit to your cause, and start seeing results. Be sure to pay attention! So, which is better? Direct-to-garment or screen printing? Dye sublimation or heat press? Read on to learn more!

The Top Four T-Shirt Print Design Options

Screen Printing

Screen printing is the process of transferring a stenciled design onto a flat surface, usually made of paper or fabric material. Using a mesh screen, ink, and a squeegee or straight blade, you can transfer virtually any image you’d like onto a new surface, as long as it’s flat. Aside from fabric and paper, it’s also possible to screen print onto other types of surfaces, such as wood, metal, glass, and plastics.

Advantages of screen printing

Screen Printing is considered to be the highest quality printing by many professionals. It’s also widely known as one of the most cost-effective options for printing your own clothing. The process is compatible with nearly all types of fabric. The print will most likely last longer than the material printed and will survive many more washes than other printing methods. Meaning? Your design is screen-printed to last.

Plus, screen printing is one of the fastest and most affordable options for printing large quantities of one specific design. So, if you’re looking to ramp up production, you could easily bust out about 25 pieces with one design.

Disadvantages of screen printing

While there are many good things about screen printing, there are a few points to consider. For one, if you’re printing small quantities or using a bunch of different designs, it’s not going to be the most cost-effective option. It becomes more expensive when printing small batches or using a plethora of larger designs. Also, the more colors needed, the bigger the bill.

Overall feedback on screen printing

If you have a high volume already and you’re filling a ton of orders left and right, screen printing may be a suitable solution for your needs. However, if you’re a new company or working with a smaller budget, you may find other methods of printing to be more cost-effective.

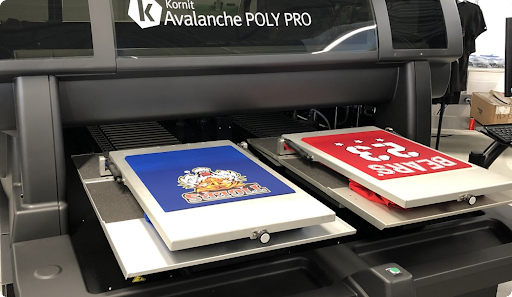

Direct-to-Garment Printing (DTG)

Direct to garment, also known as DTG, refers to a distinct method that prints a design straight onto clothing. In comparing DTG printing vs screen printing, the former requires a DTG printer, which is equipped with specialized ink to print directly onto a piece of clothing. The ink will soak into and fuse with the fabric to become a permanent part of the garment. This method makes it easier to create prints on clothing that will likely not peel or crack easily.

Advantages of direct-to-garment

There are many benefits of the direct-to-garment process. First, it can be the faster and more affordable method of printing, depending on the quantity. Detailed designs pop more using this DTG process, and it’s much easier to add different colors to highlight the incredible detail. There’s no need to keep inventory because, if you have your own modified inkjet printer for DTG printing, you can print only what customers purchase on order. which makes storage space for backstock a non-issue. It’s also ideal for print on demand services.

Disadvantages of direct-to-garment

Direct-to-Garment can be great for specific projects, depending on what you’re trying to accomplish. However, the overall feedback is that printing in larger quantities is more tedious, time-consuming, and costly. This method should be used for one-off prints and very detailed artistic or entrepreneurial endeavors.

Aside from the excessive costs and production difficulties, the process is time-consuming. Not to mention, it’s much less compatible with non-cotton fabrics. This could mean a shorter shelf life for the product.

The pros outweigh the cons with DTG

Across the board, there is an overwhelming number of advantages in using direct-to-garment printing methods for new clothing brands. The profitability is high, and it’s perfect for quick-witted entrepreneurs starting a new business with a small budget. It minimizes risk by allowing subscribers to try new designs using an eco-friendly DTG process.

Dye Sublimation

Dye sublimation is an advanced digital printing technology that uses heat to transfer an image to a designated surface or substrate. Dye or “digital” sublimation has become a standard for designing apparel, signs, and banners.

The printing process using dye sublimation requires two steps. First, you print the graphics onto transfer paper using the sublimation printer and ink. Then heat is used to transform the graphics into gas, which then bonds to the fabric.

Advantages of dye sublimation

Dye sublimation is also an excellent printing option. It allows you to add more colors than screen printing. Plus, the result will outlast many more washes than other printing methods.

Disadvantages of dye sublimation

There aren’t many downsides to dye sublimation printing fabrics. The biggest issue that arises or causes problems is that the process is much slower than inkjet printing. There are more steps in dye sublimation. It requires additional labor, which can cause the price to be a bit higher than other processes.

One more disadvantage is a production issue that tends to happen more often with older printers. Occasionally, the fabric becomes creased or wrinkled as processed, effectively ruining both the material and the transfer print. Newer printer models have eliminated this issue by having the paper and fabric inline. The printers continue to print as the piece is drawn into the rollers.

Overall opinion of dye sublimation

There are mixed reviews when it comes to dye sublimation, but it’s an excellent choice if you need to print onto a large garment or piece of fabric. It’s also a great way to test different designs. As with direct-to-garment production, the risk of mistakes is incredibly reduced.

Heat Press

A heat press is a machine used to print a design on a chosen surface, usually a T-shirt or type of fabric acting as the substrate. It uses heat and pressure for a set amount of time to successfully transfer the desired print onto the substrate. Most heat presses work best when applying patterns to different fabrics. Still, there are specific presses out there that can print designs onto other objects, such as coffee mugs, hats, notebooks.

There are two main types of heat presses, manual and automatic. If you’re going to be doing high volume, the automatic option is your top choice.

Advantages of using the heat press method

The heat press method is a fast, affordable option for printing small quantities of different designs. The simplicity of the process and accessible equipment open the possibilities of printing at home. You can apply virtually any design element you’d like to any part of the fabric or garment in use. Whether you’re looking to add more colors or want to brighten up an old shirt with metallics or glitter, the heat press method will add a unique element.

Disadvantages of using the heat press method

Unfortunately, the heat press method tends to be costly and takes much longer to print large quantities. Heat-sensitive fabrics are often not compatible with heat pressing either. Hence, there are not nearly as many options to choose from, and profitability isn’t very high.

Overall review of using heat press

Overall, the heat press is perfect if you’re a “hands-on” type of person who likes to take control. However, it can be risky to invest in equipment if you can’t make up for the expenditures. Depending on your business model and the situation, it may be better to use a professional to print your products.

Conclusion

When it comes down to it, selecting direct to garment or screen printing, or any other kind of printing method depends on what kind of shirts you plan to sell. Generally, DTG is best for printing on the front and back, and sublimation is best for all-over print. Yet, screen printing is always a great fallback option if you’re printing larger quantities.

Printbest uses quick and affordable DTG printing to produce T-shirts, hoodies and other items. Want to get started with profitable print on demand? Visit Printbest to learn how